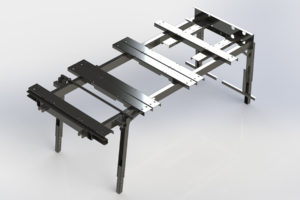

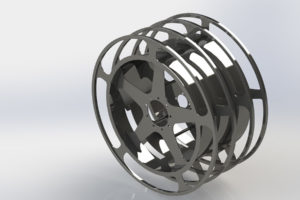

Among our diverse custom fabrication capabilities, Standard Technologies offers both traditional and advanced welding services on state-of-the-art equipment to ensure that our clients receive repeatable, verifiable quality fabrications, weldments, and sub-assemblies.

We train, test, and audit our welding personnel against our Weld Procedure Specifications (WPS), and utilize third-party calibration and internal auditing of our equipment to validate our high quality standards. Using the latest manufacturing software and technology, our welding department achieves unparalleled precision on every job.

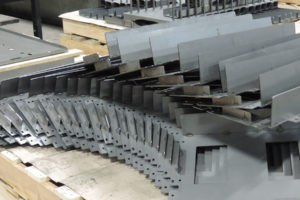

Our automated robotic welding capabilities provide clients with:

- Better utilization of labor resources — Allowing for allocation of experienced welders to work on low-volume precision projects.

- Cost savings — Yielding higher production volumes while reducing manual labor, consumable materials, and lead times.

- Quality control — Offering a consistent, repeatable process by reducing variables associated with human error.

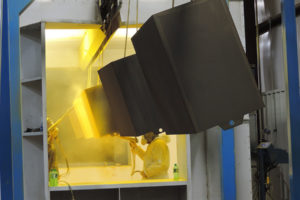

Standard Technologies is your one-stop shop for production. We also offer CNC laser cutting, material forming, powder coating, and a number of other services to complete your project entirely in-house.

Because we can perform all of our manufacturing processes in-house, our team maintains complete control over lead time, cost, and quality to ensure that we deliver our customers the best product with every order. We are fully equipped to manufacture high- and low-volume orders, as well as to prototype new parts. Our ISO 9001:2015 quality standards position us to meet the process-controlled specifications that our clients demand.

To find out more about our welding capabilities, contact our team today.