Standard Technologies offers customers high-performance laser cutting as both a part of our fabrication process and as a standalone service.

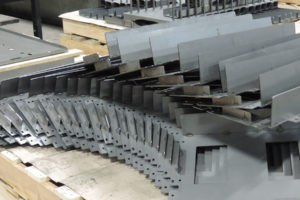

We utilize the latest tooling and technology to fabricate laser-cut sheet metal parts for OEMs and manufacturers across industries, including agriculture, construction, transportation, commercial, energy, and many more.

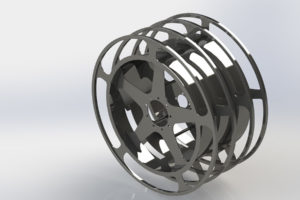

Our CNC laser cutting equipment consists of 2-axis flying optics lasers with a lens assembly carrying a beam of laser light over the surface of the sheet metal. The laser cutting head flies over the work piece — held stationary on the table without any material clamping — at speeds as high as 25 m (82 ft.) per minute, achieving speed and precision unmatched by traditional mechanical cutting methods, while leaving a mirror-smooth edge.

All of our laser cells are supported with the latest nesting software for quick turnaround and optimum material utilization. Additionally, we are equipped with an automated material handling system, which enables lights-out manufacturing capabilities.

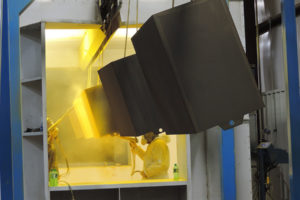

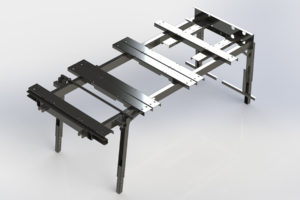

Standard Technologies is your one-stop shop for production. We also offer CNC material forming, robotic welding, powder coating, and a number of other services to complete your project entirely in-house.

Our ability to perform the laser cutting process in-house gives us complete control over lead time, cost, and quality, ensuring that we deliver our customers the best product with every order. We are fully equipped to manufacture high- and low-volume orders, as well as to prototype new parts. Our ISO 9001:2015 quality standards position us to effectively meet the process-controlled specifications that our clients demand.

To learn more about our laser cutting capabilities for your next project, contact us today.