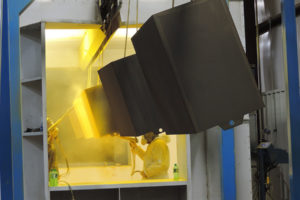

Among our diverse metal fabrication services, Standard Technologies offers custom material forming.

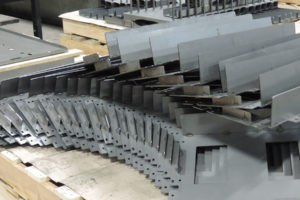

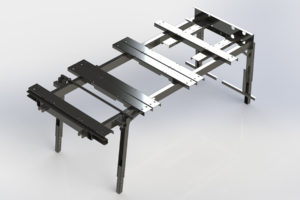

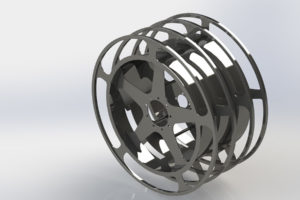

Combining decades of operator experience with advanced forming machinery and equipment, we can provide a wide spectrum of precision bending and machining capabilities for complex parts.

Prior to production, our engineering team will evaluate various methods of forming parts according to your exact specifications, thereby avoiding the need for costly custom tooling. Our back-gauging and CNC-controlled machines ensure that your parts are always formed with quality, consistency, and efficiency.

By utilizing in-house material forming equipment, we achieve several benefits for our clients:

- Cost savings — By forming instead of welding, we reduce manual labor, consumable materials, and lead times while yielding higher production volumes.

- Product integrity — By overseeing all steps of the production process, we ensure minimal distortion or deformation on the workpiece.

- Quality control — A consistent and repeatable process enhances quality by reducing variables associated with human error.

Standard Technologies’ ability to perform material forming processes in-house gives us complete control over lead time, cost, and quality, ensuring that we deliver our customers the best product with every order. We are fully equipped to manufacture high- and low-volume orders, as well as to prototype new parts. Our ISO 9001:2015 quality standards position us to effectively meet the process-controlled specifications that our clients demand.

For more information on our material forming capabilities, contact Standard Technologies today!